Addressing Challenges To Foster Sustainable Manufacturing

Hydrogen is key to advancing sustainable manufacturing by replacing fossil…

Nano Copper as A Lubricant Additive Has Significant Advantages

Nanoparticles, such as nano-copper, offer significant advantages like super sliding,…

The Lubricant Industry Can Significantly Reduce Its Environmental Footprint

The “A Closer Look at Sustainable Lubricants” paper explores the…

Lubricants and Tribology – Enhancing The Efficiency and Durabil...

The “Handbook of Lubrication and Tribology” covers the concepts and…

Copper Nano Lubricant for High-End Application

The study “Preparation of Copper Nano Lubricant for High-End Application”…

The Hidden Danger Of ZDDP Based Lubricants

The research paper delves into the impacts of organophosphate compounds…

Nasa Reported That The Hydrogen Atmosphere Can Accelerate The Brittleness of Metals

The NASA Contractor Report on “Hydrogen Environment Embrittlement of Metals”…

How The Article of Friction Surface Phenomena is Related to Cuprum’s Technology

The article “Friction Surface Phenomena”, published in 1995 by G.P….

The Efficacy of Copper-based Additives in Our Cuprum Oil’s Products

The article on the study of “Multi-Phase Friction and Wear…

How the Journal of Central South University Related to Cuprum’s Products

The article “Preparation of nano-copper as lubrication oil additive”, published…

How Zinc’s Multifunctional Properties Revolutionized Lubrication Technology

Zinc, or ZDDP, has long been the go-to lubrication technology…

Surprising Impact of Copper Lubricant on Engine Performance Givin...

Rafe Britton, representing Neol Copper Technology to meet with the…

Substituting Zinc with Copper in Engine Oils

The exploration of substituting zinc with copper in engine oils,…

NEOL’s CuGlide Technology by Rafe Britton

ZDDP has been very toxic additive either for the environment…

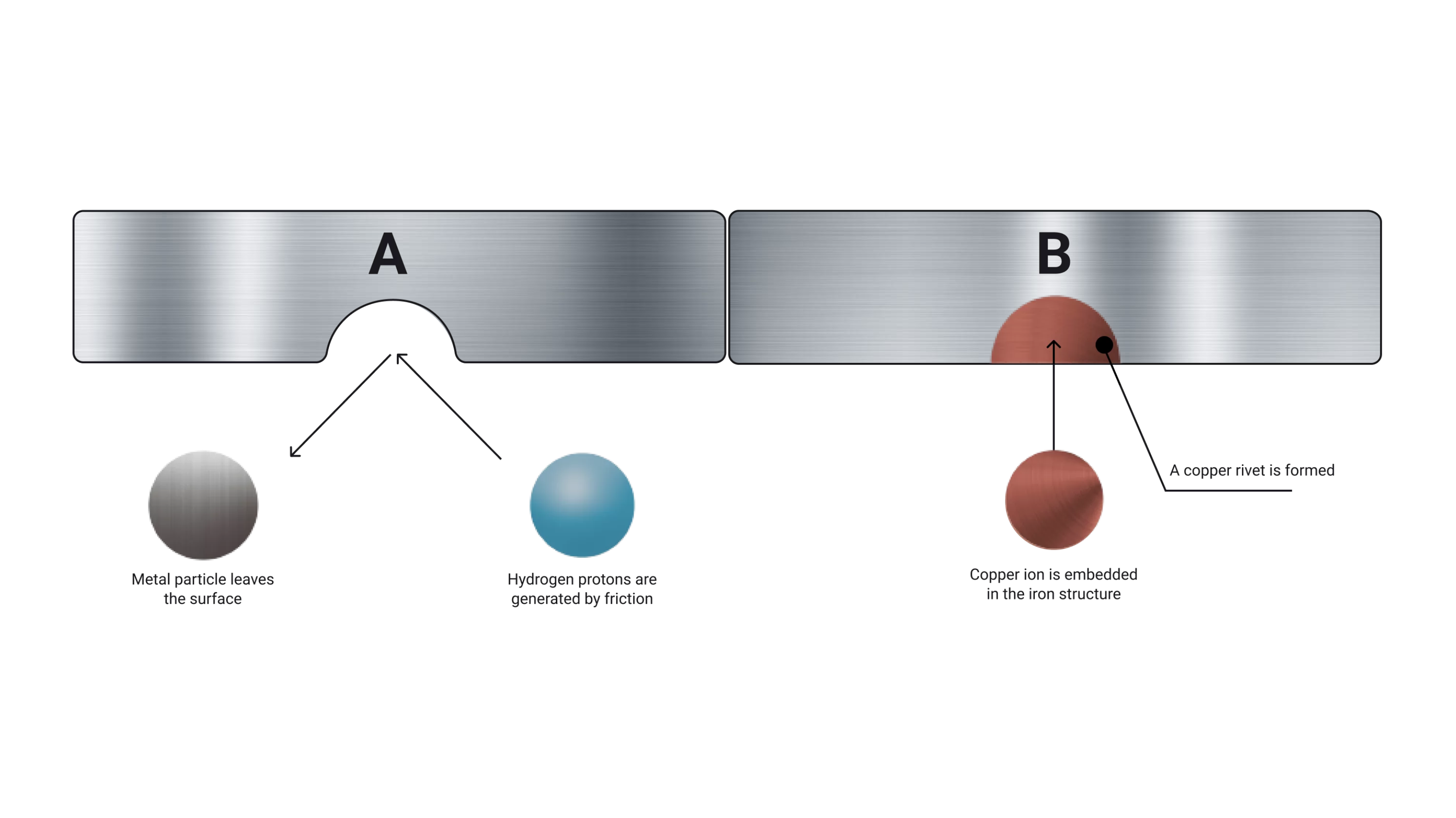

The “Hydrogen Wear” Phenomenon by Rafe Britton

In this video, Rafe Britton explains the concept and the…

“How NEOL’s CuGlide Technology Solves the Issue of Hy...

Cuprum powered by Neol is using Neol’s CuGlide Technology as…

Contact us to order

‘s

additive has

an entirely different chemical composition compared to the conventional technology

‘s

additive has

an entirely different chemical composition compared to the conventional technology